Aluminium Clamps vs. Other Materials Which is Better?

In the world of electrical components, choosing the right type of clamp can significantly impact performance and durability. For many electricians and engineers, the debate often centers around aluminium clamp and their counterparts made from steel and copper. This blog post aims to provide a comprehensive comparison between these materials, highlighting the advantages of aluminium clamps while sharing practical insights and tips for maintenance. By the end, you'll have a better understanding of which clamp material is best suited for your needs.

Comparison of Aluminium Clamps with Steel and Copper Clamps

Advantages of Using Aluminium Clamps

Customer Experiences and Success Stories

Key Considerations When Choosing Clamp Material

How to Maintain Aluminium Clamps

Comparison of Aluminium Clamps with Steel and Copper Clamps

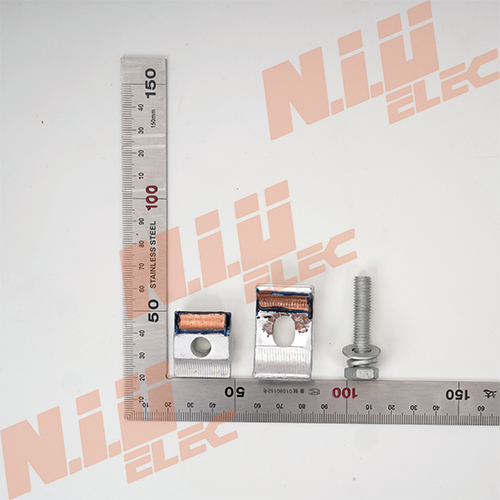

When it comes to electrical clamps, the primary materials in contention are aluminium, steel, and copper. Aluminium clamps are lightweight yet strong, making them a popular choice for a variety of applications. Steel clamps, on the other hand, offer exceptional strength and durability but can be heavy and prone to rust. Copper clamps provide excellent conductivity and are highly resistant to corrosion but can be expensive and less flexible.Aluminium clamps, like the CAPG Copper and Aluminium Parallel Groove Clamp, are designed to connect aluminium and copper conductors effectively. This unique design allows for versatility in accommodating different cable sizes on each side. In contrast, steel clamps may require additional coatings to prevent rusting, and copper clamps might need extra flexibility to fit various conductor types.Overall, aluminium clamps strike a balance between strength, weight, and corrosion resistance, making them a versatile choice for many electrical applications. This flexibility is further enhanced by advanced forging technology, which increases the mechanical strength of aluminium clamps, ensuring they can withstand significant pressure and wear over time.

Advantages of Using Aluminium Clamps

One of the biggest advantages of aluminium clamps is their weight. Being lighter than steel and copper, aluminium clamps are easier to install and handle, reducing the physical strain on workers. This can lead to increased efficiency and decreased installation time, particularly in large-scale projects.Another advantage is cost-effectiveness. Aluminium is generally cheaper than copper and, in many cases, less expensive than steel. This makes aluminium clamps a budget-friendly option without compromising on performance or durability. Additionally, aluminium is highly resistant to corrosion, which means these clamps can last longer in harsh environments compared to their steel counterparts.Lastly, aluminium clamps offer excellent thermal and electrical conductivity. This ensures stable and efficient connections, reducing the risk of overheating and electrical failures. The CAPG Copper and Aluminium Parallel Groove Clamp, for example, utilizes a special design to achieve uniform pressure along the clamp, enhancing its overall performance and reliability.

Customer Experiences and Success Stories

Many customers have shared positive experiences with aluminium clamps, particularly in terms of ease of installation and long-term performance. For instance, a project manager from a large construction firm noted that switching to aluminium clamps significantly reduced their installation time and labor costs. They also observed fewer maintenance issues over time, attributing this to the corrosion-resistant properties of aluminium.Another customer, an electrical engineer, highlighted the versatility of aluminium clamps in accommodating different conductor sizes. They praised the CAPG Copper and Aluminium Parallel Groove Clamp for its ability to connect both aluminium and copper conductors efficiently, stating that it improved the overall quality and stability of their electrical connections.These success stories underscore the practical benefits of using aluminium clamps in various applications, from residential wiring to large industrial projects. The positive feedback from customers reinforces the reputation of aluminium clamps as a reliable and cost-effective solution.

Key Considerations When Choosing Clamp Material

When selecting the right clamp material for your project, several factors should be considered. First, assess the environmental conditions where the clamps will be used. If the environment is prone to moisture or corrosive elements, aluminium clamps' corrosion-resistant properties make them an ideal choice.Next, consider the weight and ease of installation. For projects where weight is a critical factor, such as overhead wiring or mobile installations, the lightweight nature of aluminium clamps can be a significant advantage. Additionally, if your project involves frequent adjustments or changes, aluminium clamps' ease of handling can save time and effort.Finally, evaluate the cost implications. While aluminium clamps are generally more affordable than copper and some steel options, it's essential to balance cost with performance requirements. Ensure the chosen clamp meets the necessary mechanical and electrical standards for your specific application.

How to Maintain Aluminium Clamps

Proper maintenance is crucial to ensure the longevity and performance of aluminium clamps. Regular inspections should be conducted to check for signs of wear or damage. Clean the clamps periodically to remove any accumulated dirt or debris, which can affect their performance.Lubricating the moving parts, such as bolts and nuts, can help maintain smooth operation and prevent seizing. In the case of the CAPG Copper and Aluminium Parallel Groove Clamp, the materials of the bolt and nut can be customized based on customer requirements, including options like hot-dip galvanized steel and stainless steel for added durability.Lastly, ensure that the clamps are securely fastened and that the connections are tight. Loose connections can lead to electrical failures and pose safety risks. By following these maintenance tips, you can extend the lifespan of your aluminium clamps and maintain optimal performance.

Choosing the right clamp material is a critical decision that can impact the efficiency, cost, and durability of your electrical projects. Aluminium clamps offer a balanced combination of strength, weight, and corrosion resistance, making them a versatile and cost-effective choice. With proper maintenance and careful consideration of your specific needs, aluminium clamps can provide reliable performance for years to come.

If you're considering upgrading your clamps or want to learn more about the benefits of aluminium clamps, check out the CAPG Copper and Aluminium Parallel Groove Clamp. Its advanced features and positive customer feedback make it a standout choice for various applications. Visit [website link] to explore more and make an informed decision for your next project.